ERP & Digital Transformation

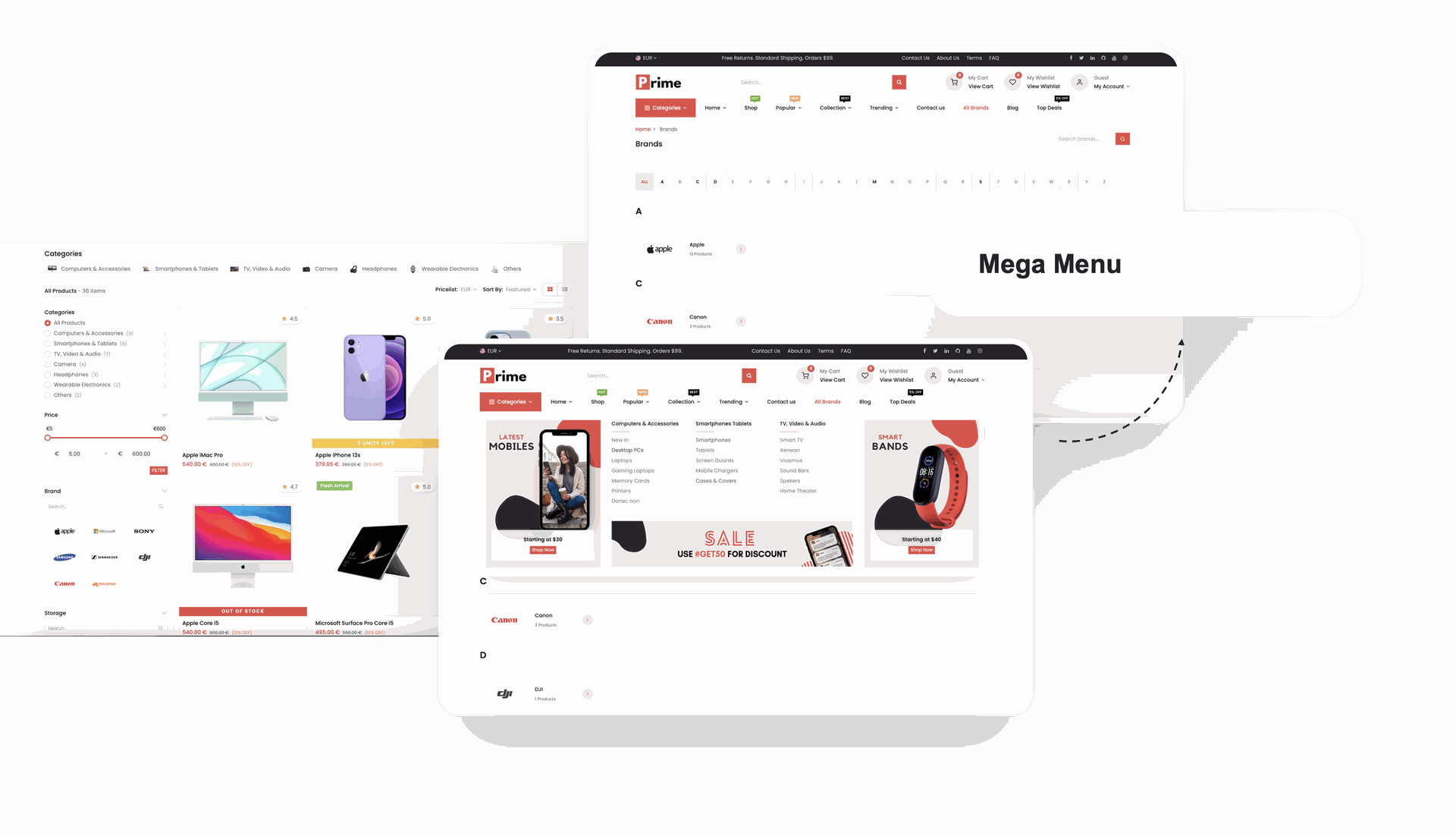

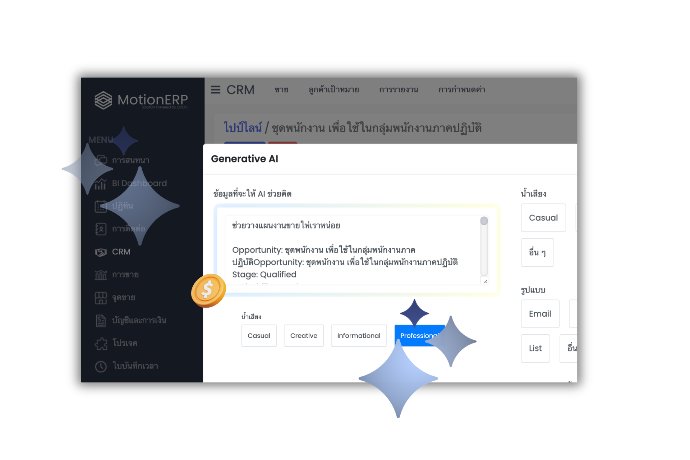

The integrated administration system is easy to use. Includes the basic business running applications that will make your organization work as a team in the online world smoothly anywhere anytime. consulting, design, and system installation.

Implementation

Consultation and systems ERP to suit each organization delivering Gap Analysis

Prototype Configuration Data Import Validation and Training

Cloud Services

ERP Cloud Service Seamlessly connects users for up to 24 hours. Desktop / Mobile / Tablet Support IOS and Android.

เราคือ Odoo Silver Partner ที่ได้รับการรับรองอย่างเป็นทางการ การันตีคุณภาพและความเชี่ยวชาญในการให้บริการโซลูชัน ERP ด้วยประสบการณ์ที่หลากหลายและทีมงานมืออาชีพ เราพร้อมช่วยคุณปรับปรุงกระบวนการทำงาน เพิ่มประสิทธิภาพ และขับเคลื่อนธุรกิจของคุณสู่ความสำเร็จ

✨ มั่นใจในคุณภาพ เลือก Dynamics Motion วันนี้!